LIME RENDER

Lime Rendering contractors GPD Contracts supply & Install Heritage approved breathable Render systems from Tellings Lime products. Specialists in restoration and New Lime Render projects in surrounding districts including Birmingham, Leamington, Worcester, Malvern, & Cheltenham.

Lime Render mortars ensure that Peiod properties function as originally designed. Allowing the structure to move as individual elements rather than as a mass. Lime render is fully breathable and provides a superb decorative finish for renovations and conversions, offers extremely high levels of flexibility and durability. Unilit hydraulic lime products conform to the European Standard ENV-4951, NHL 2-3.5 and 5.0 for natural hydraulic lime. GPD contracts employ traditional Lime Rendering methods and do not use modern plastic beads or metal beads. This provides significant benefits to the Quality of finish and longevity of the system.

For more information, click here for the Telling website.

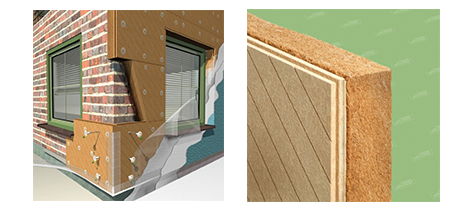

EWI for PERIOD PROPERTY

The thermal upgrading of solid wall structures and heritage buildings of historic importance creates unsurpassed challenges since over-cladding is seldom an option. The only intelligent method of improving the thermal performance of the external walls of these buildings – largely constructed in lime mortar – is to insulate internally, but the natural “breathability” and through wall performance must be fully evaluated since:

Impermeable insulation mediums can lead to severe interstitial condensation

The outer surfaces of the building can become cold & damp & thereby subject to accelerated & aggressive weather attack

Moisture trapped within the shell of the building can cause mildew & fungal growth

Synthetic & impermeable plasters, linings, coatings & decoration are all potential contributors to fabric damage

Modern day insulation materials are a barrier to heat transfer, whereas wood fibre & other natural mineral slabs perform more like a storage radiator

Replacing Sand & Cement with Traditional Lime Render

Sand Cement Render has been used on period properties for many years, since inception in 1940's. However, the suitability to buildings constructed of clay bricks and lime mortar is increasingly better understood. Key differences relate to levels of movement and breathability which results in premature cracking, delamination often resulting in damp problems within the property.

For more information please click here to visit the Period Property UK website

Removing Sand Cement Render and replacing with a traditional lime render system simply returns the building to its original design and function.

Common Problems

On the right, top image shows a stainless steel, clay coated lath. The lower image shows why this is an unsuitable substrate with a timber lintel and some blow bricks.

Image above shows a timber lintel and blown bricks

Image above shows clay fused brick mesh. This is mechanically fixed with stainless steel screws to create a suitable substrate for lime render when overcoming unsuitable or excessively porous brickwork.

Traditional methods still utilised

Traditional techniques and skills are still used for the application of lime render.

Note there is no use of metal or plastic beads. Corners and reveals are formed with timber during levelling and scratch coating.

Image above shows traditional timber formed corners & reveals during levelling and scratch coats.

Image above shows window reveals formed with lime render coat applied before painting.

EXAMPLES OF PERIOD PROPERTY RENDER

Lime Rendering Contractor in Worcester

Breathable EWI for Period properties.