About METAL FRAME RENDER

In general terms, when considering render solutions for metal frame buildings, the following applies:

Insulation is generally contained within the metal frame

An approved Render board is mechanically fixed to the secondary metal frame (SFS)

Base coat render & fibre reinforcing mesh is completed to a flat sponge finish

Primer & finishing silicone or acrylic coloured top coat

Generally this applies to new build projects and can be used within both domestic & commercial schemes.

Recommended Installers

Increased thermal performance within both the refurbishment & new build construction markets.

GPD Contracts have worked closely with our suppliers for a number of years. Our partners as listed below all carry certified systems for use on metal frame constructions.

The Insulation within an EWI system is often mechanically fixed with a cementitious adhesive. However, as with all industries, manufacturers are striving for improvements to their systems. The fixing methods below from STO showcase this:

Knauf Exterior Aquapanel

Knauf Exterior Aquapanel is widely approved with our partners

A Project specific specification is available

When installing, close attention to the system providers

Specification is critical to the longevity of the finished render system

Particular attention to detailing around openings, corners, movement joints should be evident

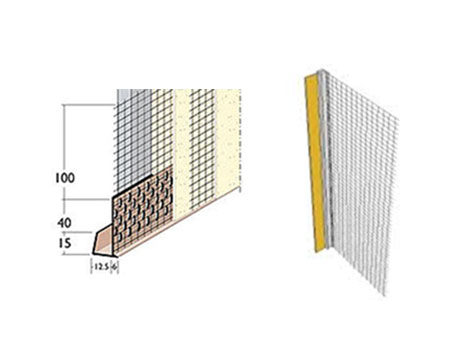

PVC bead, Insect Mesh & APU Bead

On ventilated systems, the use of board edge closing PVC Beads and insect mesh are integral to the long-term performance

Frame seal, or APU Beads, are an innovative stop bead for use around windows. The bead includes a self-seal feature, which generally negates the need to apply a silicone seal on completion of render application. Frame seals also incorporate a removable protective strip (the yellow strip on the image above). This ensures a sharp clean line when complete.